Component Introduction

Jacky Technology (Dongguan) Co.,LTD is a professional manufacture which is in custom, high-precision Mold design and components processing and CNC machining services We has been providing quality products and service by strong and comprehensive capabilities ,advanced technology and scientific management on production and technique.

For more than 10 years. JAC-TEC relying on highly trained satff along with extensive manufacturing experience and international advanced equipment,JAC-TEC has established long-term cooperation with with many world-renowned companies and University

- The University of Texas at Austin

- The Chinese University of Hong Kong

- Huazhong University of Science and Technology

- Beijing Institute of Technology

- Bosch

- M&M MAQTEC

- Bielomatik

- Denso

- Nidec

- Topstar

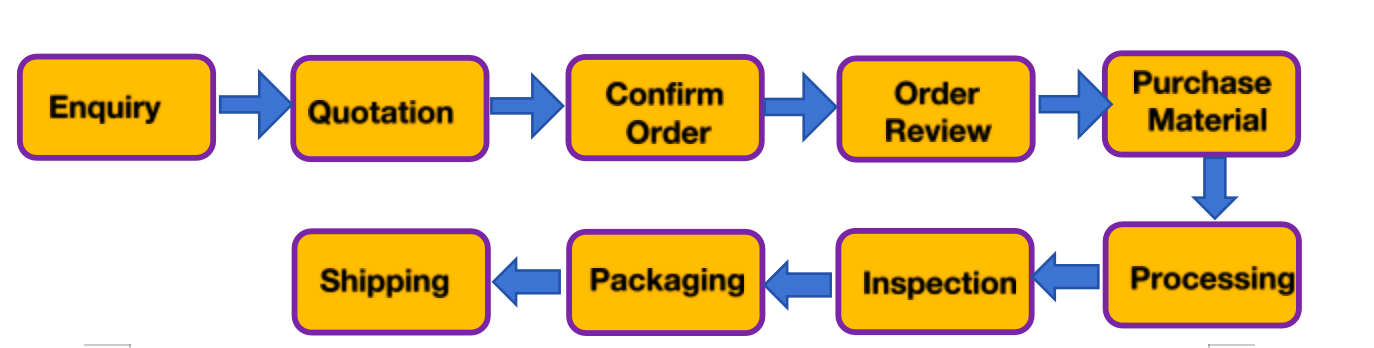

Process from Enquiry to Delivery

We handle your orders from enquiry to delivery, offering high-precision mold component and machining parts customization, Fast quotes, Excellent quality ,Delivery on time and Reliable service, Over 10 years of focused on providing high-precision machine parts and customized mold components design technical expertise and machining craftsmanship

Taking Customer demand as the driving force to produce and creat the first-class products,The Zero Defect as the standard of measure quality effectiveness and to guaranteed quality, it will be processed strictly according to the material.

Our company import high precision machine for improving the quality of precision mold component and machining parts and decreasing the delivery time which increase our customer satisfaction .the machining tolerance of our machine can reach +/-0.001mm

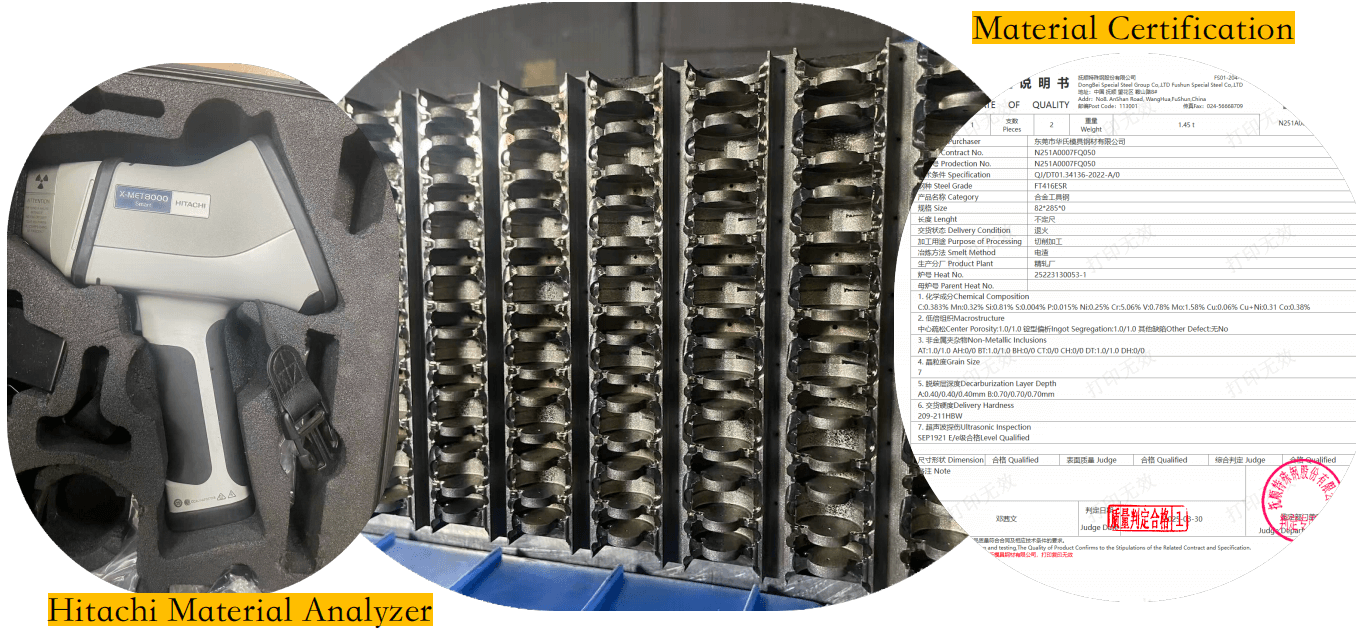

Authentic and High-Quality Materials

In modern engineering and product design, the selection of material is critical to ensuring durability, performance, and sustainability.SKD11, PX5, SKD61, NAK80, S316L, BeCu, A5052, A7075, 718L, G5,G20.G2, Acrylic,POM,PEEK,Teflon etc. (ASSAB, BOHLER ,Hitachi has long-term cooperation), we can provide the original material certification and also test report by our company Hitachi and Nikon material analyzer (The third party SGS and CTI has long-term cooperation.

We ensure products meet drawings and accuracy, with a strict inspection system BSI ISO9001:2015 for reliable results

Let us complete your component delivery more faster.

Which kind mold component to do?

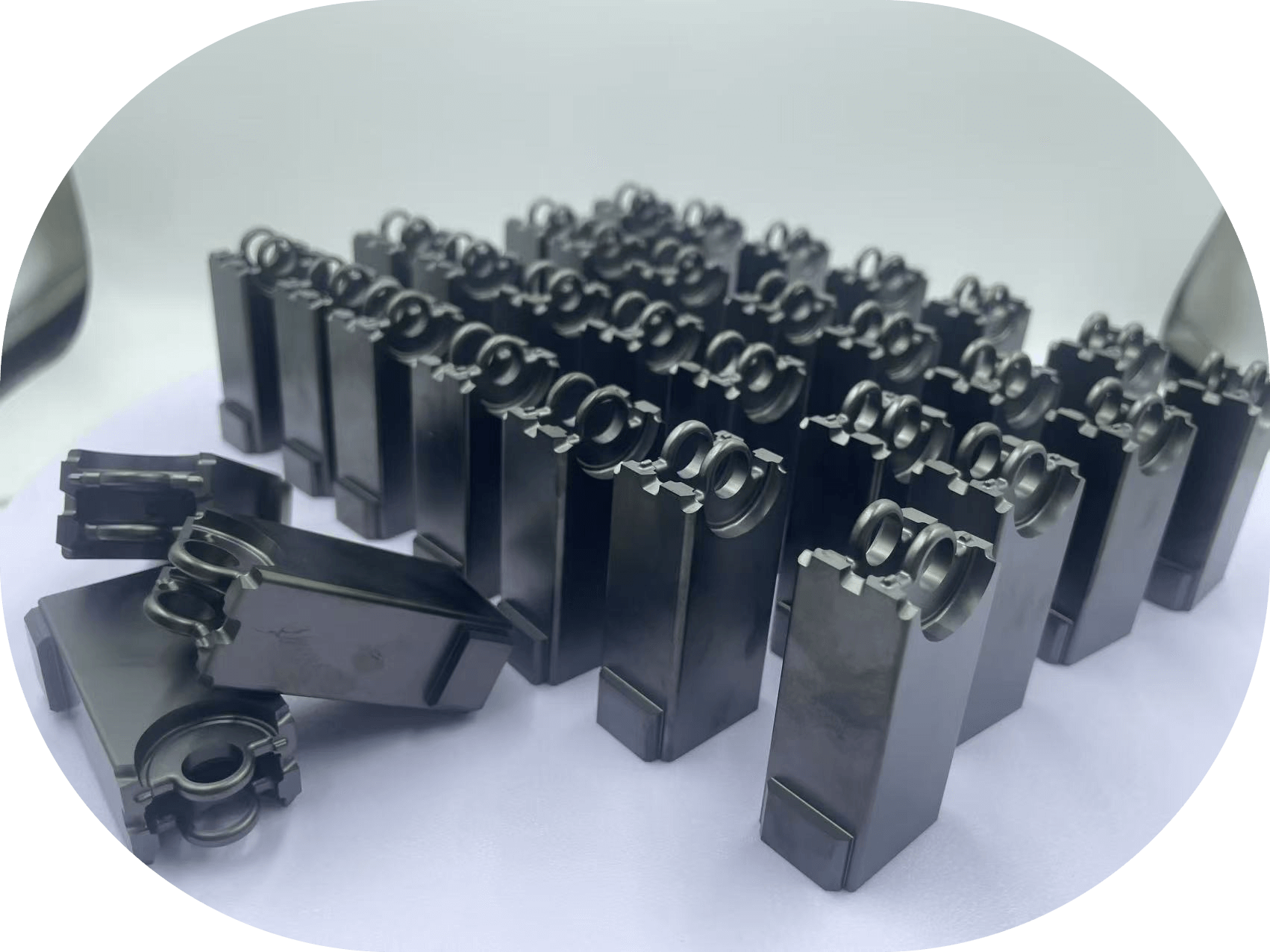

Automotive electronic mold component

Connector mold component

Cosmetic mold component

Carbide steel mold parts

Hardware stamping mold components

Mechanical mold parts

Medical precision mold component

Pen case and nib precision mold component

Plastic injection mold parts

PET perform bottle cap mold components

Die casting mold components

Thread core inserts

Ejector pins and ejector sleeves

Hot runner

Please provide your drawings, CAD or 3D data ensures faster response; and we’ll submit the quotation and delivery date within 1 hour.

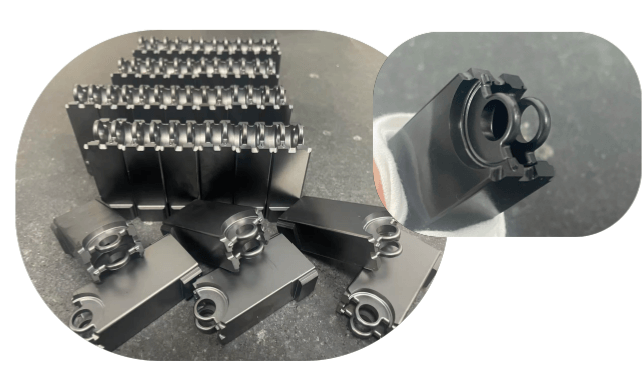

Process Details

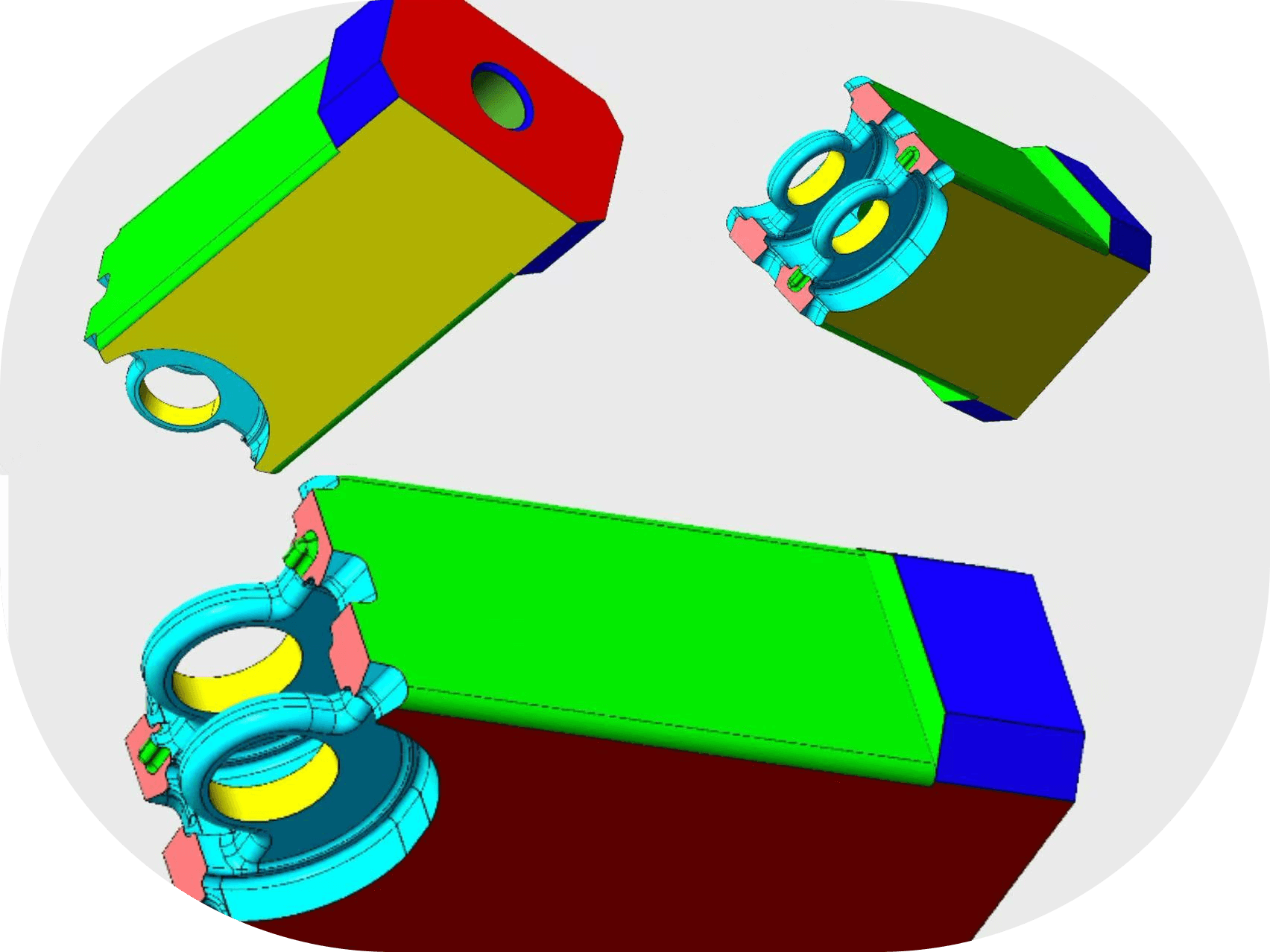

How we make your 3D model to the true products?

Let us show this item mold component processing;

Material:DH31-EX,

Heat treatment:HRC48~52,

Coating:DLC

1: CNC did the electrode

2: EDM to roughing

3: ZEISS CMM test the first sharp

4: Wire cut separate them into 1

5: EDM to precision machining

6: CMM final test

Order Review Meeting

order review meetings serve as critical quality gates for mold component design and processing teams to ensure successful project execution.

1. Clarify technical specifications and customer expectations Order documentation review (2D/3D data package verification)

2. Conduct Design for Manufacturability (DFM) analysis and Technical feasibility simulation (Moldflow analysis results)

3. Identify potential production challenges,

4. Develop risk mitigation strategies

5. Establish cross-departmental alignment.(design, production, quality.PMC).Action item assignment with clear ownership.

We will provide material certification from original material supplier and also test by oursleves Material analyzer

If you need precision mold component machining and CNC machining services or are looking for a suitable precision component machining factory, please choose Jac-Tec,Jac-Tec provides one-stop machining and production services for precision mold component and machining parts and assemblies for new energy, medical equipment, electronics .robotics, commercial equipment, and so on. You can conatct with project manager Maggie email: maggie@maqmtec.com Tel: +86 13632861056

Accuracy

Wire Cut R >0.2mm

EDM Roughness can meet Ra0.02um,

Surface can do mirror Polishing

Tolerance +/-0.001mm

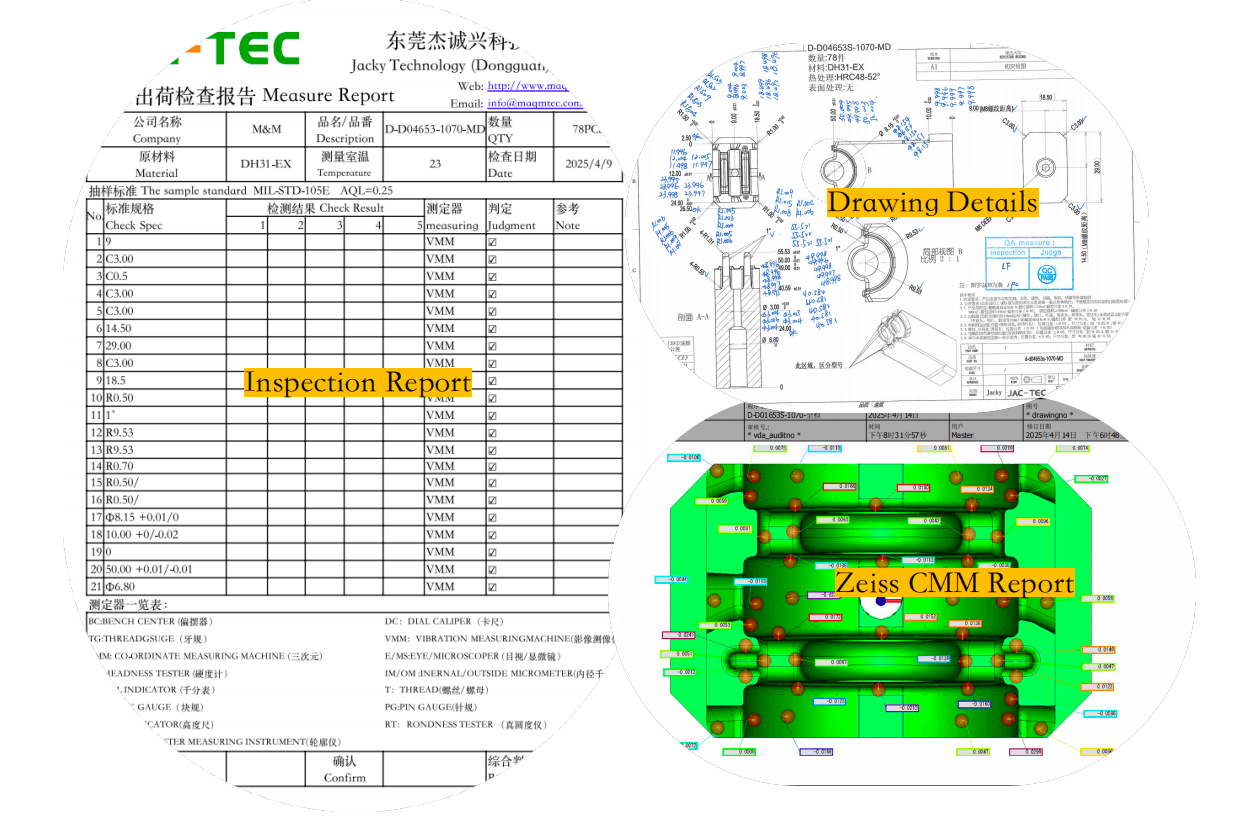

Shipping document

1:Inspection report

2:Drawings details

3:ZEISS CMM report

4:Material certification (If customer require)

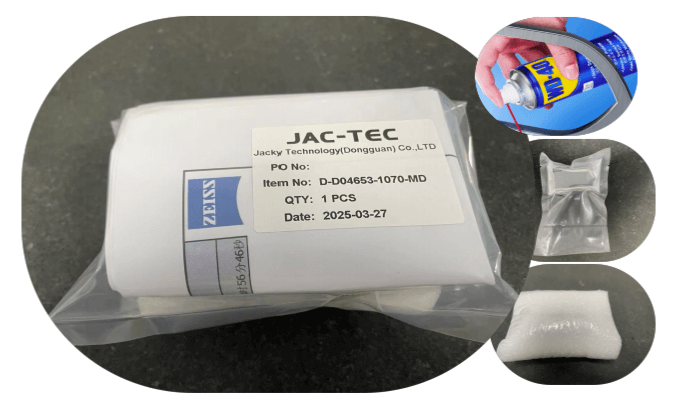

Packaging

1:Products are sprayed with WD-40 anti-rust oil to prevent rust

2:Products are individually vacuum packed one by one

3:Products are packed in EPE to prevent damage

4:Put all report and drawings inside the packaging

5:Stick label (PO No.,Item No.,QTY,Date) on products ,if customer have special request will according to customer requirement

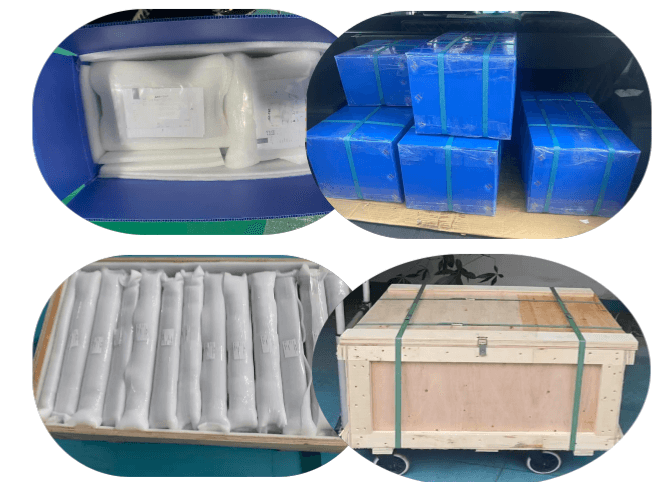

Boxes

We have two difference Box

1:Blue plastic boxes:Protect products better than cartons during transportation

2;Wooden Box:is easy to open and close by twisting buckle without screws.

Logistic

Selecting the optimal logistics provider requires a focus on three core principles: security, reliability, and suitability.Customized Solutions for Optimal Fit Mold component and machining parts demands alignment with specific business needs: Cost-Efficiency: Balancing air freight speed vs. sea freight economy based on cargo urgency and budget and specialized handling: UPS,DHL,Fedex,SF,KYE,Deppon

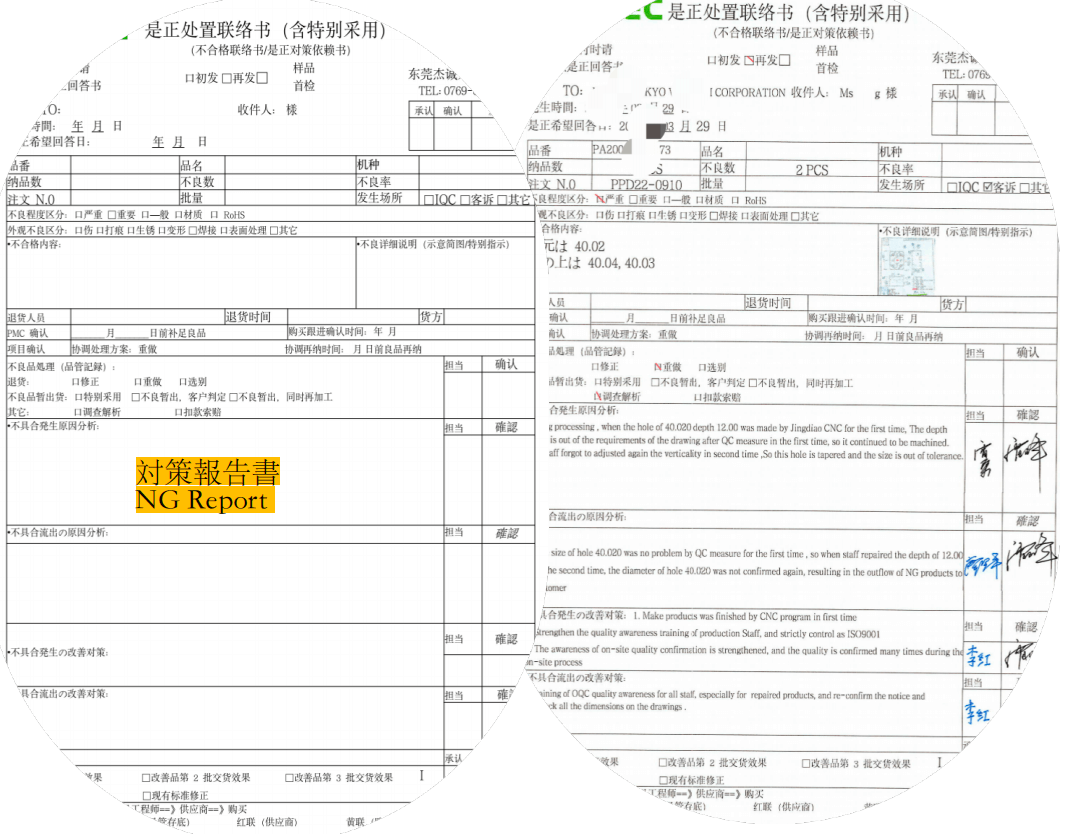

When NG Happen

Our Quality Manager Edahiro San will have meeting with all team member to discuss,then develop SOPs (Standard Operating Procedures) and APQP and release the NG report 対策報告書 to customer redo new products free for them soon

1:Analysis of the reason why NG happen in factory 不具合発生原因分析

2:Analysis of the reason Why NG shipping to customer不具合流出の原因分析

3:Improvement to reduce NG happen 不具合発生の改善对策

4:Improvement to stop shipping NG out to customer不具合流出の改善对策

Here’s what our clients say

Don’t just listen to us. Here are what people say about us.

I already talked to them and explained that you are my best and most reliable supplier, and that you’ve never let us down., just like we’ve always worked together over the years.

—Javier

I very much appreciate your partnership. I want you to know that you are our gold-standard- that we measure other suppliers by your efficiency! You are wonderful

—Eduardo

I saw your parts,Your parts are very perfect .Thank you.In Germany we can’t make a better quality than you.In future i plan to work more close with you.We both are working well.Thank you so much for your support.

—Jenny Böse

What do you think about your quality. It was great .the quality level is the same like Japan company .i think it is a bit higher. You have done a great job.The final product is good. You have been able to successfully fabricate them.Thank you so much for your team.

—JUNICHI

If you have urgent processing and technical problems that cannot be solved, If you need precision mold component machining and CNC machining services or are looking for a suitable precision component machining factory, please choose Jac-Tec,Jac-Tec provides one-stop machining and production services for precision mold component and machining parts and assemblies for new energy, medical equipment, electronics .robotics, commercial equipment, and so on. You can conatct with project manager Maggie email: maggie@maqmtec.com Tel: +86 13632861056