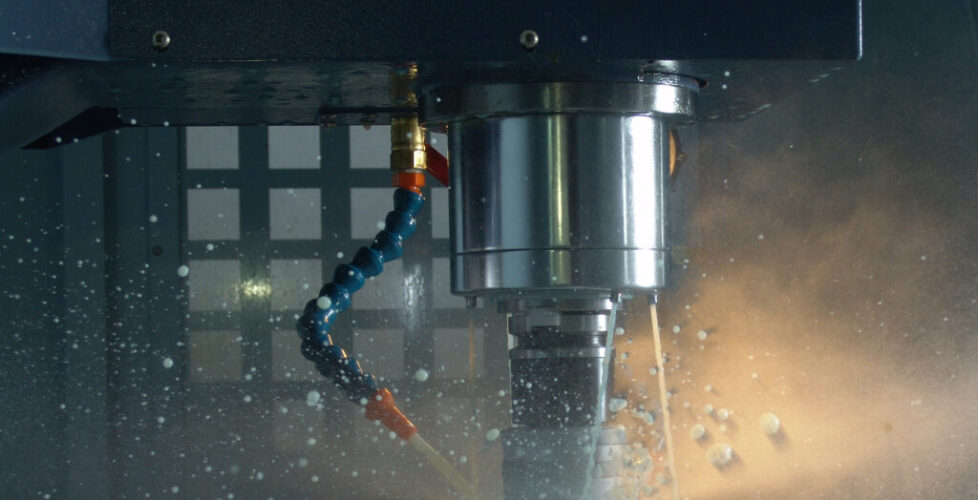

CNC Parts

Computer Numerical Control (CNC) technology has revolutionized the manufacturing industry, enabling the production of highly precise and complex parts with remarkable efficiency. CNC products, ranging from automotive components to aerospace parts, have become indispensable in various sectors. This article explores the evolution, applications, and benefits of CNC products, as well as their impact on modern manufacturing.

CNC technology traces its roots back to the 1940s and 1950s when the first numerical control (NC) machines were developed. These early machines used punched tape to control their operations, a significant advancement over manual machining. However, it wasn’t until the advent of computers in the 1970s that CNC technology truly began to flourish. The integration of computers allowed for greater flexibility, precision, and automation in machining processes.

Over the decades, CNC technology has continued to evolve, incorporating advancements in software, hardware, and materials. Today’s CNC machines are capable of performing a wide range of operations, including milling, turning, drilling, and grinding, with unparalleled accuracy and speed.

CNC products are utilized in a myriad of industries, each benefiting from the precision and efficiency that CNC technology offers. Some of the key applications include:

Now CNC machines are used to manufacture engine components, transmission.and we are focused on CNC machining more than 15 years ,Jacky Technology (Dongguan) CO., LTD will try our best to do service for you

If you need precision mold component machining and CNC machining services or are looking for a suitable precision component machining factory, please choose Jac-Tec,Jac-Tec provides one-stop machining and production services for precision mold component and machining parts and assemblies for new energy, medical equipment, electronics .robotics, commercial equipment, and so on. You can conatct with project manager Maggie email: maggie@maqmtec.com Tel: +86 13632861056