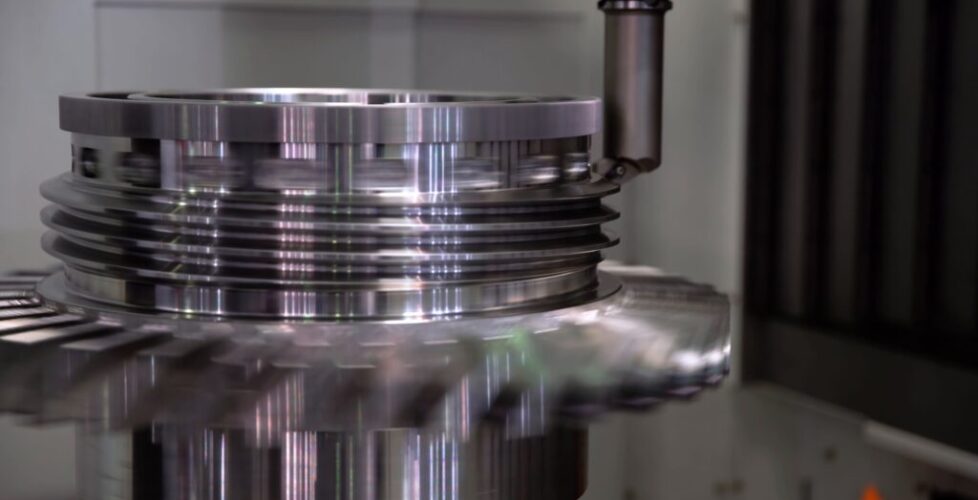

How CNC working

CNC machining involves the use of pre-programmed computer software to control the movement of machinery and tools. The process begins with the creation of a digital design using Computer-Aided Design (CAD) software. This design is then converted into a set of instructions, known as G-code, Jacky Technology (Dongguan) CO.,LTD the CNC machine can interpret. The G-code controls the movement of the machine’s axes, as well as the speed and feed rate of the cutting tools.

CNC machines can perform a variety of operations, including milling, turning, drilling, and grinding. These machines are capable of working with a wide range of materials, such as metals, plastics, ceramics, and composites. The precision and repeatability of CNC machining make it ideal for producing parts with intricate geometries and fine details.

Advantages of CNC Machining

1.Precision and Accuracy: CNC machines can achieve extremely tight tolerances, often within microns. This level of precision ensures that each part produced is consistent and meets the required specifications.

2.Efficiency: CNC machining is highly automated, reducing the need for manual intervention. This leads to faster production times and increased productivity.

3.Flexibility: CNC machines can be easily reprogrammed to produce different parts, making them versatile and adaptable to changing production needs.

4. Complexity: CNC machining can produce complex shapes and features that would be difficult or impossible to achieve with traditional machining methods.

5. Reduced Waste: The precision of CNC machining minimizes material waste, leading to cost savings and more sustainable manufacturing practices.

If you need precision mold component machining and CNC machining services or are looking for a suitable precision component machining factory, please choose Jac-Tec,Jac-Tec provides one-stop machining and production services for precision mold component and machining parts and assemblies for new energy, medical equipment, electronics .robotics, commercial equipment, and so on. You can conatct with project manager Maggie email: maggie@maqmtec.com Tel: +86 13632861056.

CNC machining is used in a wide range of industries and applications. In the aerospace industry, it is used to produce critical components such as turbine blades and engine parts. In the automotive industry, CNC machining is used to manufacture engine blocks, transmission components, and custom car parts. The medical industry relies on CNC machining to produce surgical instruments, implants, and prosthetics. Additionally, CNC machining is used in the electronics industry to create precise components for devices such as smartphones and computers.

Jacky Technology (Dongguan) CO.,LTD CNC machining has become an indispensable technology in modern manufacturing. Its ability to produce high-precision, complex parts with efficiency and flexibility has made it a cornerstone of many industries. As technology continues to advance, CNC machining will likely play an even greater role in shaping the future of manufacturing.