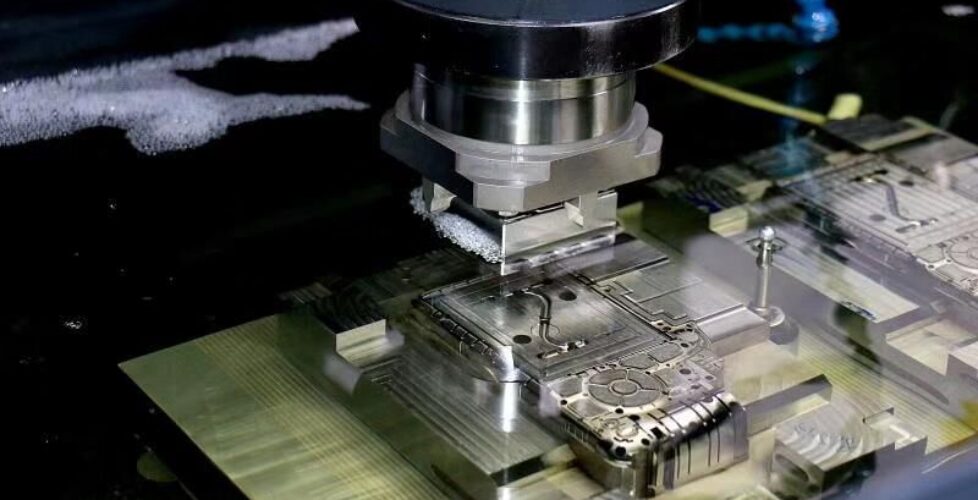

What is the Wire Cut?

Wire cutting, also known as wire-EDM (Electrical Discharge Machining), is a precision machining process used to cut complex shapes and fine details in electrically conductive materials. This process is widely used in industries such as aerospace, automotive, and tool and die making Jacky Technology (Dongguan) CO.,LTD due to its ability to produce intricate parts with high accuracy and fine surface finishes

Wire cutting involves the use of a thin, electrically charged wire, typically made of brass or copper, which serves as the electrode. The wire is guided along a programmed path to cut through the workpiece. The process works by generating a series of electrical discharges (sparks) between the wire and the workpiece, which erode the material. A dielectric fluid, usually deionized water, is used to flush away the eroded particles and to cool the workpiece and wire

1. Wire Electrode: The thin wire that conducts electricity and cuts the material.

2. Power Supply: Provides the electrical energy needed to generate the sparks.

3. Dielectric Fluid: Acts as a coolant and flushes away debris.

4. CNC Control System: Guides the wire along the programmed path with high precision.

Advantages of Wire Cutting

– High Precision: Capable of achieving tolerances within microns.

– Complex Shapes: Can produce intricate and complex geometries that are difficult or impossible with conventional machining.

– Fine Surface Finish: Produces smooth surfaces with minimal post-processing required.

– Material Versatility: Can cut a wide range of electrically conductive materials, including hardened steels, titanium, and composites.

Applications of Wire Cutting

– Tool and Die Making: Used to create molds, dies, and punches with high precision.

– Aerospace: Manufacture of complex components such as turbine blades and engine parts.

– Medical Devices: Production of intricate parts for surgical instruments and implants.

– Automotive: Fabrication of precision components for engines and transmissions.

Limitations of Wire Cutting

– Material Conductivity: Only effective on electrically conductive materials.

– Cutting Speed: Generally slower compared to conventional machining methods.

– Cost: Higher initial investment and operational costs due to the complexity of the equipment and the need for continuous wire replacement

Wire cutting is a highly specialized and precise machining process that offers significant advantages for the production of complex and intricate parts. Its ability to work with a variety of conductive materials and produce fine details makes it an invaluable tool in modern manufacturing. However, Jacky Technology (Dongguan) CO.,LTD it is essential to consider its limitations and costs when selecting it for specific applications.

If you need precision mold component machining and CNC machining services or are looking for a suitable precision component machining factory, please choose Jac-Tec,Jac-Tec provides one-stop machining and production services for precision mold component and machining parts and assemblies for new energy, medical equipment, electronics .robotics, commercial equipment, and so on. You can conatct with project manager Maggie email: maggie@maqmtec.com Tel: +86 13632861056.