Which PVD Coating JAC can do

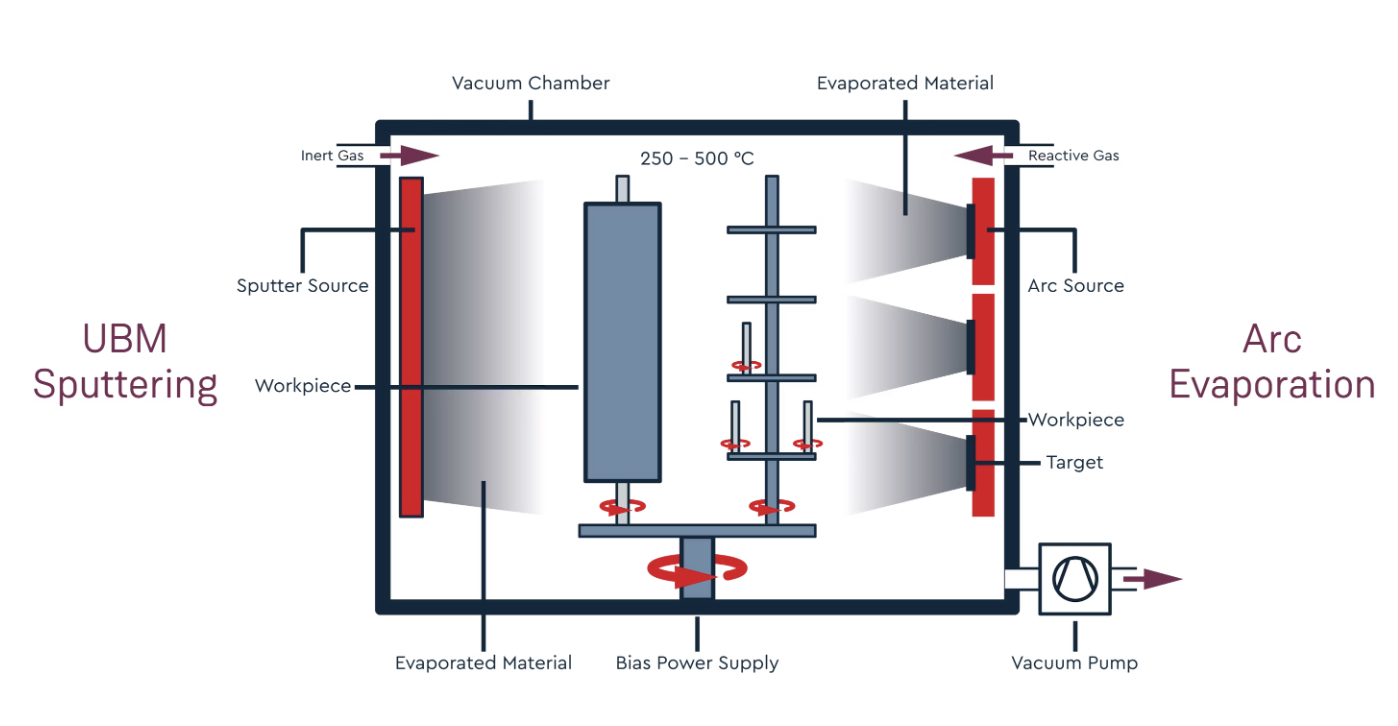

PVD coating process is used for the deposition of coatings made of nitrides, carbides and carbonitrides of Ti, Cr, Zr and alloys like AlCr, AlTi, TiSi on a large range of tools and components. Applications include cutting and forming tools, mechanical components, medical devices and products that benefit from the hard and decorative features of the coatings. The typical process temperature for PVD coatings is between 250 and 450 °C. In some cases, PVD coatings can be deposited at temperatures below 70 °C or up to 600 °C, depending on substrate materials and expected behavior in the application. The PVD coating process suits multiple kinds of materials. This inclused PVD stainless and other kinds off metal substrates to meet diverse industry needs.

What are the primary advantages of PVD coatings?

PVD coatings reduce long term costs and increase efficiency. Costs are reduced due to longer-lasting tools and increased cutting speeds and feeds, which results in higher productivity. PVD coated tools can be run with dry or with minimum lubrication (or release agents in the case of forming tools) saving both operating and recycling costs. PVD coatings on mechanicals reduce friction and wear and improve performance and reliability.

How should tools and components be prepared for coating?

Prior to coating, substrates (tools and components) need to be free of any foreign matter, oils and grease on the surfaces that are to be coated, but also in all other areas. The cleaning process is an essential element that determines the adhesion and thus influences the performance of the coated part or tool.

What part or tool geometries can be PVD coated?

The PVD,coating process, is a line of sight process which requires substrates to be rotated in the chamber (from single to triple rotation) in order to achieve the required homogeneous coverage and thickness. Coating of inner diameters in PVD is restricted to a depth equal to the diameter of the opening

What is the turnaround time for coating?

Typical lead times are 1 to 5 days. Test parts and samplings take more time as fixturing and process design is required.

Do you also provide DLC PVD coating service?

Certainly! Diamond-Like Carbon (DLC) coatings can be deposited by different technologies such as PVD arc, PVD sputtering and PACVD processes. Various performance characteristics, such as hydrogenated and non-hydrogenated DLC coatings, can be achieved by selecting the appropriate technology and deposition parameters.

If you need precision mold component machining and CNC machining services or are looking for a suitable precision component machining factory, please choose Jac-Tec,Jac-Tec provides one-stop machining and production services for precision mold component and machining parts and assemblies for new energy, medical equipment, electronics .robotics, commercial equipment, and so on. You can conatct with project manager Maggie email: maggie@maqmtec.com Tel: +86 13632861056.