Jacky Technology (Dongguan) CO., LTD is the factory supplier for Mechanical Machining and Mold component Manufacturing in the Electronics Industry.

Mechanical machining and mold components manufacturing are complementary forces in the electronics industry. JAC-TEC machining excels in precision and flexibility for low-volume or complex parts, mold-based processes deliver cost-effective scalability for mass production. Together, they enable the creation of smaller, smarter, and more sustainable electronic.

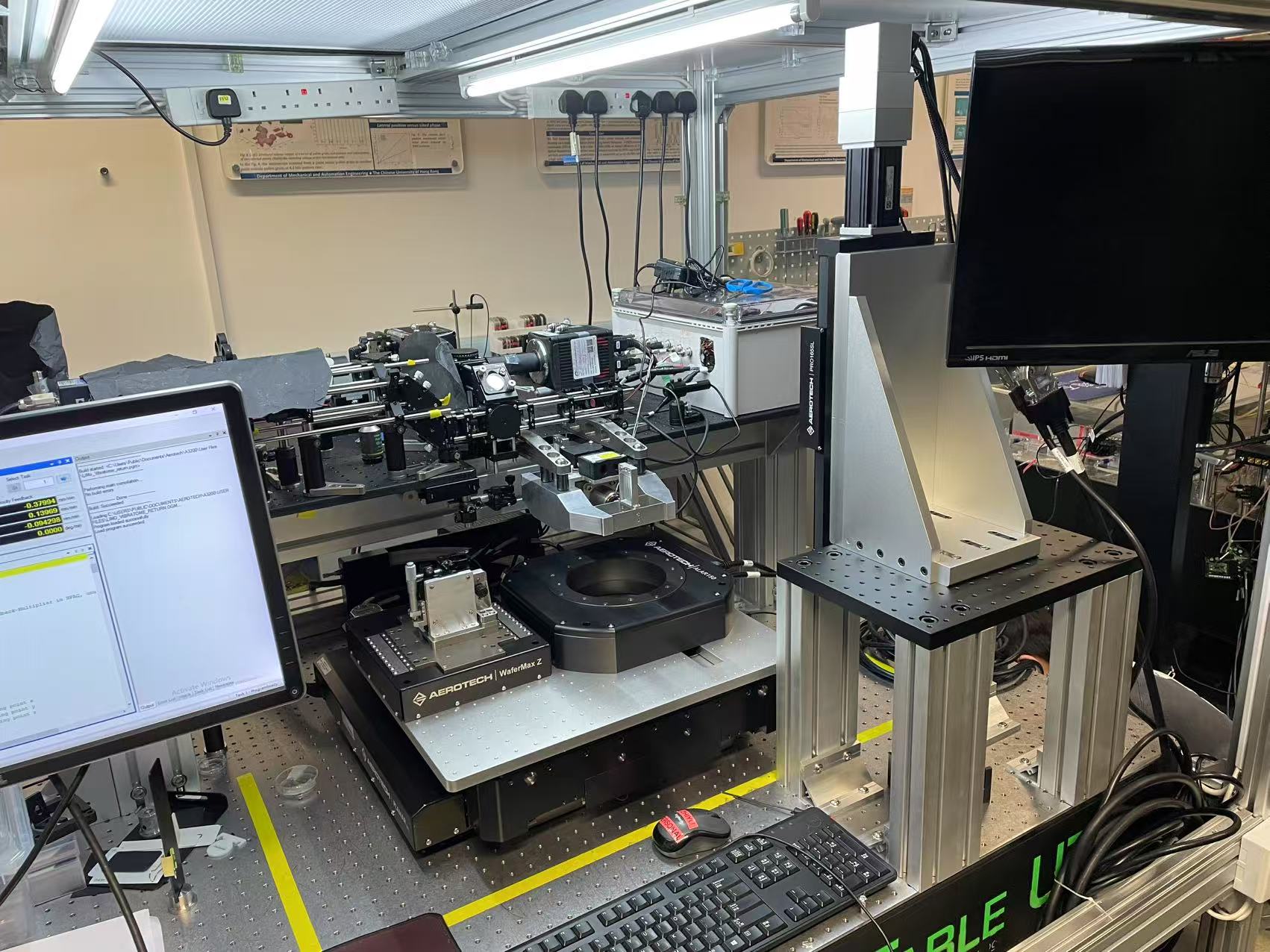

Now we are part with The Chinese University of Hong Kong and The University of Texas at Austin to do the Optical instruments for scientific research (wire-cut thinkness is 0.3mm), did the Precision nozzle assembly (hole position is 0.001mm) for ITW inkjet coding.and ship every month 15 sets bluetooth headset mold to customer,

1. Machining parts: Precision for Critical Components

including CNC milling, turning, and laser cutting, is the backbone of manufacturing parts that require micron-level accuracy.

– Micro-Scale Components:

– Connectors :

– Heat Sinks:

Sensor Housings:

– Material Versatility:

Machining handles advanced materials like titanium alloys , PEEK and ceramic composites ensuring compatibility with diverse electronic applications.

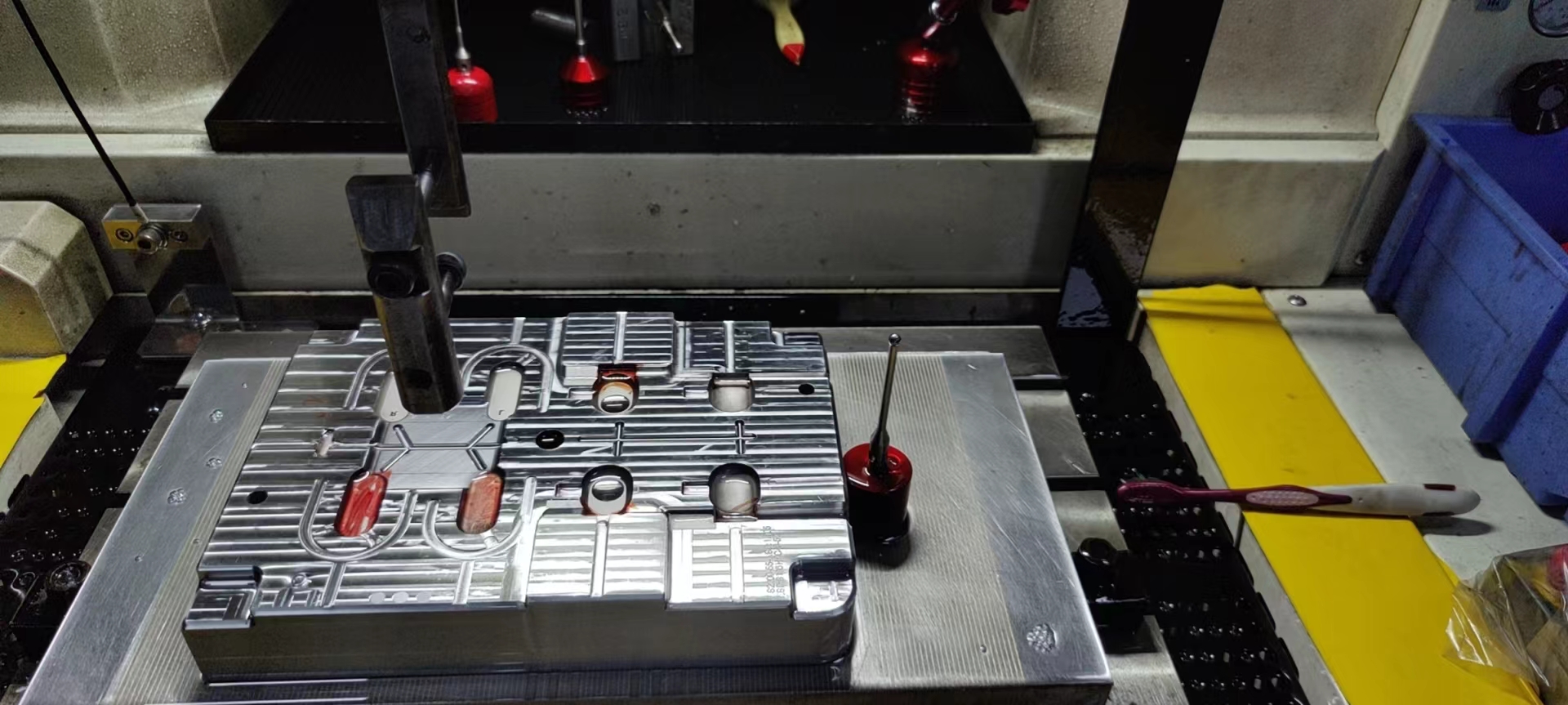

2. Mold Parts Machining: Enabling Mass Production

– consumer electronics shells are mass-produced using high-precision injection molds. Mold components machining ensures smooth surfaces, precise tolerances, and consistent quality .

– Micro-Injection Molding: For tiny components like SIM card trays or micro-USB port covers, molds component with ultra-fine cavities are machined to tolerances below 0.001 mm.

– Metal Die-Casting mold component:

such as internal brackets for servers or antenna housings for 5G devices.

Optical instruments for scientific research

Bluetooth headset mold

Jacky Technology (Dongguan) Co., Ltd. is a manufacturer specializing in mold components and high-precision machining parts manufacturing

CONTACT US

Follow Us