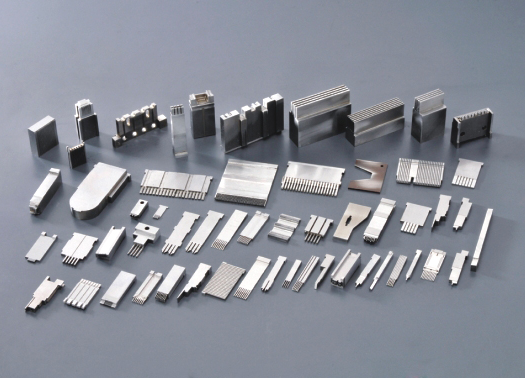

What we Supply

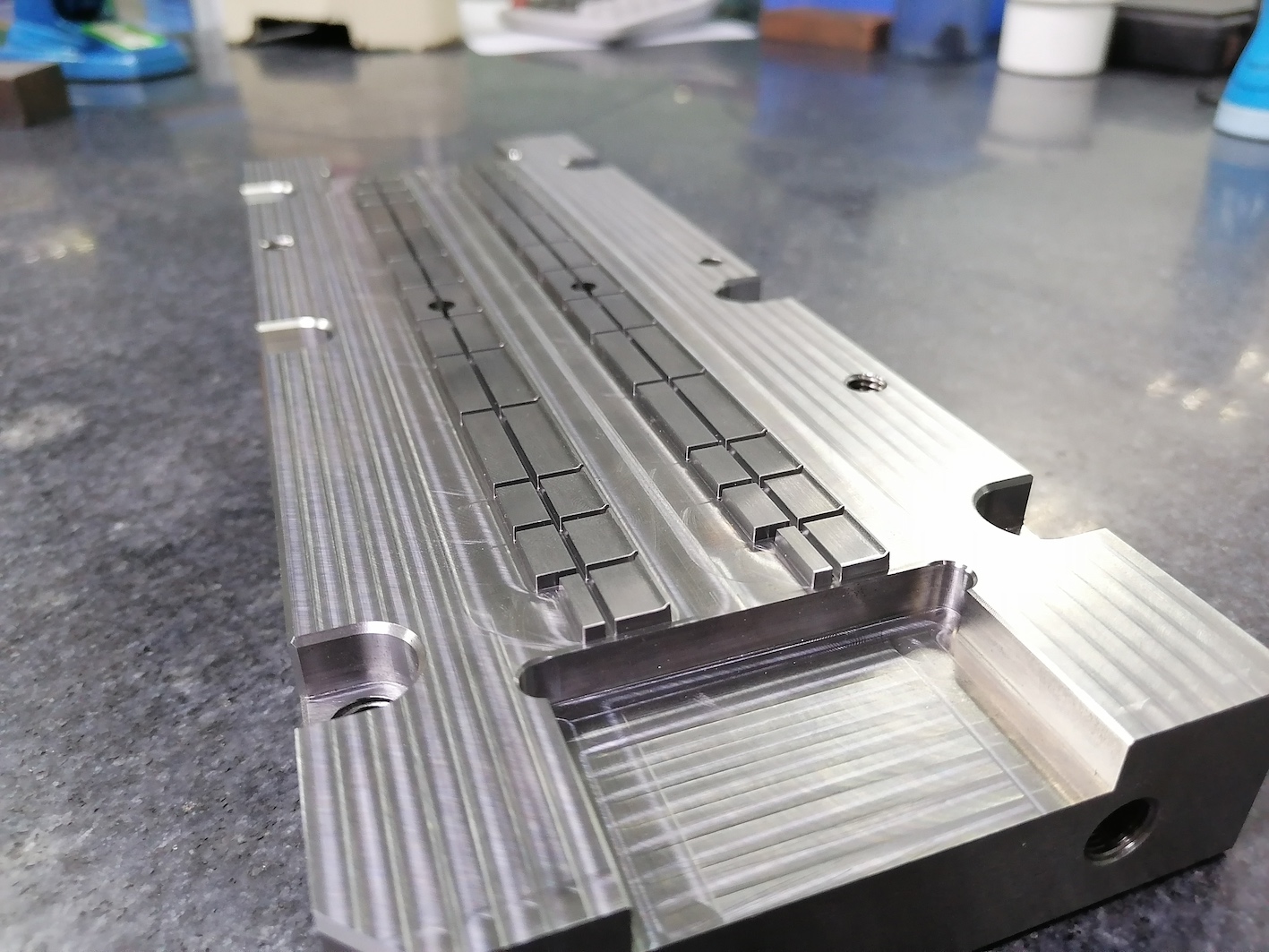

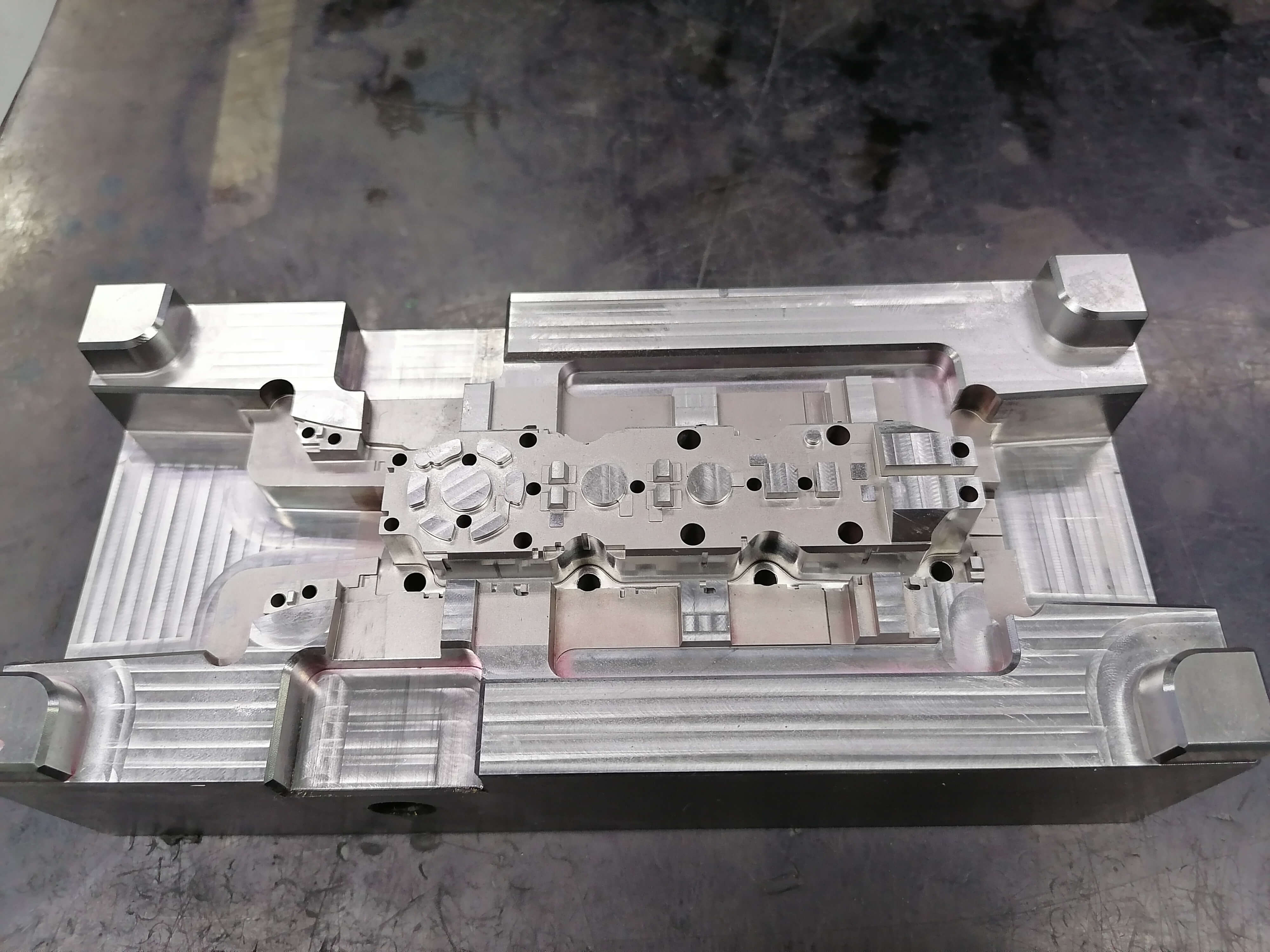

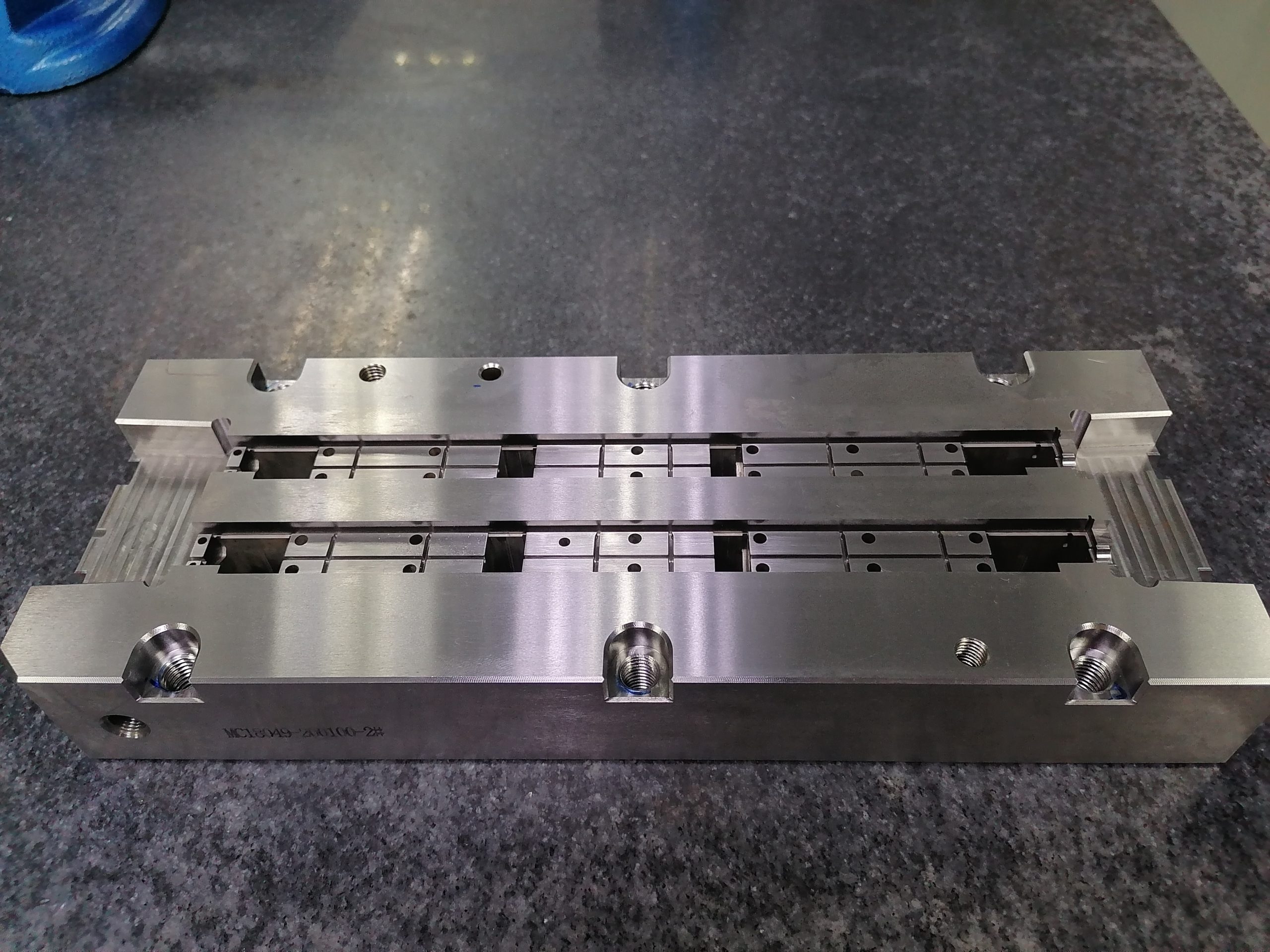

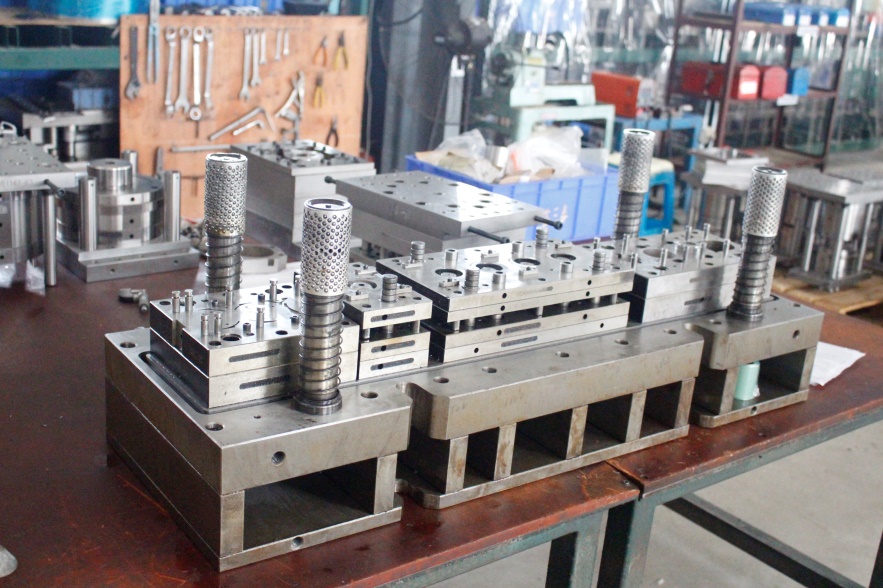

Precision Machining & Mold Components Manufacturing Solutions

Your Trusted Partner in Custom Components and Tooling,Full inspection reports with 3D scanning (ZEISS CMM)Compliance with BSI ISO 9001:2015 standards.

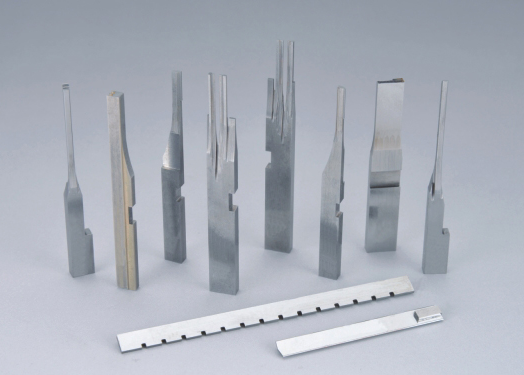

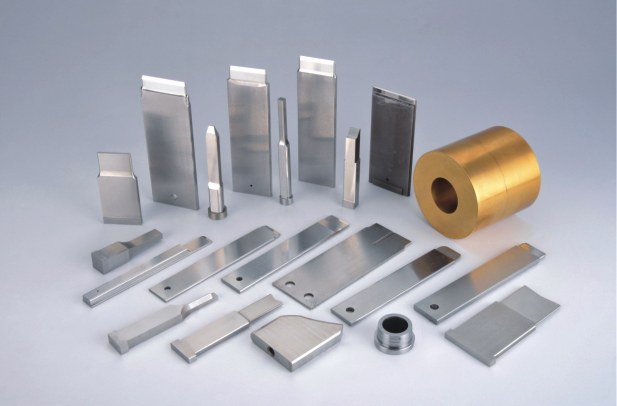

We specialize in high-precision mechanical machining and mold components for industries demanding tight tolerances and complex geometries.

Core Technologies:

–CNC Milling & Turning: Multi-axis CNC machining centers (e.g., 5-axis) capable of handling materials from aluminum to super alloys (Inconel, Titanium).

–Grinding: Surface, cylindrical, and ID/OD grinding for micron-level precision (up to ±0.001 mm).

–Wire EDM: Cutting intricate shapes in hardened steels or exotic materials with minimal thermal distortion.

–Lathe Machining: Ideal for small, high-precision shafts and medical components.

—–Materials Expertise:

Aluminum (6061.7075,5052,2025…)

Stainless Steel (SUS304.SUS303,S316L.1Cr13…),

Brass,

Copper,

Plastics (PEEK,Nylon,Teflon,POM,ABS,PVC,Rubber…),

Titanium,

Tungsten steel

Engineering Alloys (BeCu,Moldmax.APMC018,…..),

Steel(SKD11,SKD61,SKH51,PX5,NAK80.H13,D53,S55C,S45C.SKS3,

—–Surface Treatments:

Nitriding

Mirror polishing (Ra ≤ 0.05 μm).

PVD coatings:Chrome,DLC, TIN,TICN,TiALN,Black,Nickel,Zinc,Matte…

—– Key Applications:

Aerospace spare parts, Automotive parts, Robotics components, Hydraulic systems, and Semiconductor tooling

Design

Scientific design concept,rational R&D procedure.

Quality

100% full inspection for products appearance

Service

All service for all design.process. debug ,assembly shipping

Engineer

Evaluation to analyze every details and every step of parts

If you need precision mold component machining and CNC machining services or are looking for a suitable precision component machining factory, please choose Jac-Tec,Jac-Tec provides one-stop machining and production services for precision mold component and machining parts and assemblies for new energy, medical equipment, electronics .robotics, commercial equipment, and so on. You can conatct with project manager Maggie email: maggie@maqmtec.com Tel: +86 13632861056